Jinan Halo fresh potato chips production line machines

Composite potato chips production line

Fried type food.

Mainly ingredients: potato powder

Frying oil: palm oil

- Description

- Inquiry

Jinan Halo fresh potato chips production line machines

To make potato chips at home, you can follow these steps:

1. Choose potatoes: It is better to choose fresh, firm and large potatoes. Varieties such as Russet or Yukon Gold are great for making chips.

2. Wash and Peel: Wash the potatoes thoroughly to remove any dirt or debris. You can peel them if desired, but leaving the skins on adds extra flavor and texture to the chips.

3. Slice the potatoes: Use a sharp knife or a mandoline slicer to slice the potatoes into thin, even slices. Aim for a thickness of about 1/8 inch (3 mm) for crispier fries.

4. Soak the slices: Place the sliced potatoes in a bowl of cold water to rinse off excess starch. Let them soak for about 30 minutes. This step will help remove moisture and make the chips crispier when fried.

5. Dry the slices: After soaking, drain the potato slices and pat dry with a clean kitchen towel or paper towel. Make sure they are completely dry to prevent oil from splattering while frying.

6. Fry the chips: Heat vegetable oil or any oil suitable for frying in a deep fryer or large pot. The ideal temperature for frying potato chips is about 350°F (175°C). Add potato chips sparingly to avoid overcrowding. Fry them until golden brown, usually 3-5 minutes. Make sure to flip gently halfway through for even cooking. Avoid overcooking as it will give the chips a burnt taste.

7. Drain excess oil: Remove the fried chips with a slotted spoon or tongs, and place them on a plate lined with paper towels. This will help absorb excess oil from the chips.

8. Season the chips: While the chips are still warm, sprinkle with salt or any desired seasoning. You can get creative and enhance the taste by adding flavors like BBQ, sour cream, or grated cheese.

9. Cooling and storage: Allow chips to cool completely to room temperature. Once cooled, transfer them to an airtight container or zip lock bag to preserve their crispness.

Throughput:

100-500kg/h to choose

| DEVICE NAME | Model | Dimension(mm) | Power | Material |

| Feeding conveyor | TSJ-4600 | 4600*1000*2800 | 0.75kw | SUS304 |

| Brush washing machine | QX J-2400 | 2800*950*2720 | 3.55KW | SUS304 |

| Washing peeling machine | QPJ-2400 | 2800*950*1670 | 4.55KW | SUS304 |

| Picking line | TJX-3000 | 3000*1120*1410 | 0.55KW | SUS304 |

| conveyor | FGX-3000 | 3500*1400*3000 | 7.17KW | SUS304 |

| Potato chips slicer | QPJ-1000 | 880*770*1222 | 2.25kw | SUS304 |

| conveyor | FGX-2500 | 2500*1400*3000 | 7.17KW | SUS304 |

| Bubble Washing machine | QXJ-4500 | 4559*1931*2120 | 7.5KW | SUS304 |

| Blanching machine | PTJ-5500 | 5500*1850*1000 | 3kw | SUS304 |

| Air cooling line | FGX-5000 | 5000*1100*1800 | 3kw | SUS304 |

| Fast conveyor line | SSJ-1500 | 2000×820×1370 | 0.75KW | SUS304 |

| Frying machine heating energy can be electricity or gas diesel oil | XDL-8500 | 8500*2300*2200 | 24kw | SUS304 |

| Vibrating deoil machine | ZDS-1500 | 1500*1400*800 | 0.37KW | SUS304 |

| conveyor | FGX-3000 | 3500*1400*3000 | 7.17KW | SUS304 |

| Seasoning machine | TWJ-3500 | 3500*1200*1800 | 0.75KW | SUS304 |

| combination conveyor | SSJ-5500 | 5500*800*1200 | 0.55KW | SUS304 |

| Multi-head weigher and Packaging machine | BZJ-420/10 | 4000 *3500 *4000 | 2.2KW | SUS304 |

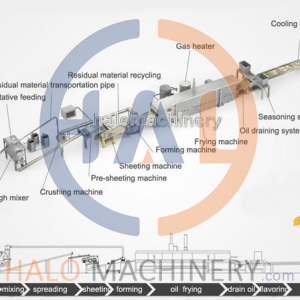

Potato chps production line layout:

Mixing lifting conveying – quantitative feeding – mixing – lifting – leveling – Leather – molding – deep fried – oil – seasoning – cooling – packaging

Machine images

Package type

The packing can be cans type and plastic package type.

Pls contact us for machine info and videos

abc@halomachinery.com

Whatsapp: +8618660119608