Jinan Halo cake production line machines

Function and Performance:

HL Series Cake Production Line is the primary choice for your production of kinds of filled custard cake, Euro-style cake and other kind of cake in various size and shape. The weight of the cake can be adjusted at the range of 10g-1000g as per customer’s requirement. This plant is known for rationalized structure, easy operation, smooth operation and high efficiency. Using advanced technology, adopting computerize programs control, the plant is widely welcomed by food manufacturers.

- Description

- Inquiry

Jinan Halo cake production line machines

Welcome contact us to get quotation for refference ,

Whatsapp: +8618660119608

Email: abc@halomachinery.com

cake production line

Function and Performance:

HL Series Cake Production Line is the primary choice for your production of kinds of filled custard cake, Euro-style cake and other kind of cake in various size and shape. The weight of the cake can be adjusted at the range of 10g-1000g as per customer’s requirement. This plant is known for rationalized structure, easy operation, smooth operation and high efficiency. Using advanced technology, adopting computerize programs control, the plant is widely welcomed by food manufacturers.

Capacity 400-500kg/h

Total power 75kw installed

Gas consumption 40CBM

Automatic cupcake processing line – Cooling tower Heart-injection cake production line Supply cake forming machine Food machinery can produce different shapes of fancy cakes according to the shape change of the baking tray mold.

All the parts of this equipment in contact with food are made of stainless steel, which is corrosion resistant and easy to clean.

The hot air circulation baking oven can be made of stainless steel or cold rolled plate according to the customer’s requirement.

The heat preservation sandwich of the oven adopts high quality heat preservation cotton, which has good heat preservation effect, high thermal efficiency and low energy consumption.

The system adopts PLC automatic control system, simple operation and stable performance.

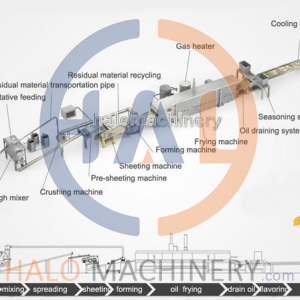

Equipment composition.

Mixer: there are traditional mixer and inflatable mixer

Forming machine: PLC program linkage control is used, only one time to adjust properly, long-term use of linkage program, double row quickly forming, stable performance.

Gas hot air circulation baking oven: the furnace adopts advanced gas combustion, hot air circulation heating method, divided into the front, middle and back up and down a total of six temperature zones, the temperature is set by the proportional motor through the butterfly valve automatic control, the temperature through the duct divided up and down to the chamber for baking food, with the advantages of fast heating, temperature stability, small changes, automatic temperature control. Thus the cake taste better fluffy, the surface color more uniform, fresh and other advantages.

Demoulding machine: Attractive demoulding machine, without changing the shape of the cake.

Core injection machine: This machine can automatically core the whole row of cakes, if it senses that a cake is not on the production line, the core injection needle will not core so as not to inject into the conveyor belt. It greatly improves the production efficiency and avoids the waste of material and cleaning process.

Production process: mixing – forming – baking – cooling – demoulding – core filling – sterilization – packaging, in between: spray oil – flip – brush – flip

CE certificate noted.